Hazard Analysis & Critical Control Points (HACCP)

HACCP is a management

system in which food safety is addressed through the analysis and control

of biological, chemical, and physical hazards from raw material production, procurement and handling,

to manufacturing, distribution and consumption of the finished product.

Planning and integration of a HACCP concept and management including daily work templates for employees in the F & B department.

Hazard Analysis Critical Control Points (HACCP) is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed. HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product. Through analysis of hazards and where they can occur, controlling and templates helps implement systems and procedures to minimize risk. Work-sheets of a safety management system will help at each and every operation in assisting in the management of critical control points.

A food safety program, however, does not just stop with HACCP.

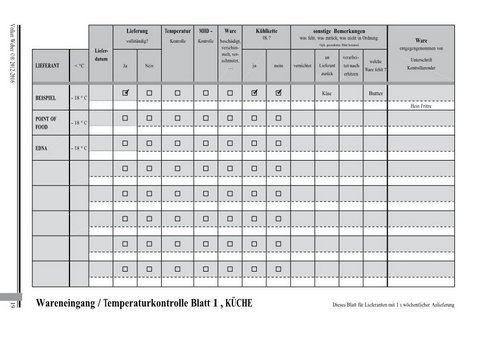

To be effective, prerequisite programs such as pest control, traceability & recall, hygiene and sanitation need to be developed and implemented. Additionally, the issue of ensuring that suppliers and distributors also have a food safety program needs to be addressed through development of ingredient specifications and a vendor assurance system.

This is an example of a HACCP manual that i wrote for a German company. It includes the

legal framework and templates for daily use by the employees.

Principle 1 - Conduct a Hazard Analysis

.The

application of this principle involves listing

the steps in the process and identifying where

significant hazards are likely to Occur. The

HACCP team will focus on hazards that can be

prevented, eliminated or controlled by the HACCP

plan. A justification for including or excluding

the hazard is reported and possible control

measures are identified.

Principle 2 - Identify the Critical Control Points

.A critical control

point (CCP) is a point, step or procedure at

which control can be applied and a food safety

hazard can be prevented, eliminated or reduced

to acceptable levels. The HACCP team will use a

CCP decision tree to help identify the critical

control points in the process. A critical

control point may control more that one food

safety hazard or in some cases more than one CCP

is needed to control a single hazard. The number

of CCP's needed depends on the processing steps

and the control needed to assure food safety.

Principle 3 - Establish Critical Limits

.A

critical limit (CL) is the maximum and/or

minimum value to which a biological, chemical,

or physical parameter must be controlled at a

CCP to prevent, eliminate, or reduce to an

acceptable level the occurrence of a food safety

hazard. The critical limit is usually a measure

such as time, temperature, water activity (Aw),

pH, weight, or some other measure that is based

on scientific literature and/or regulatory

standards.

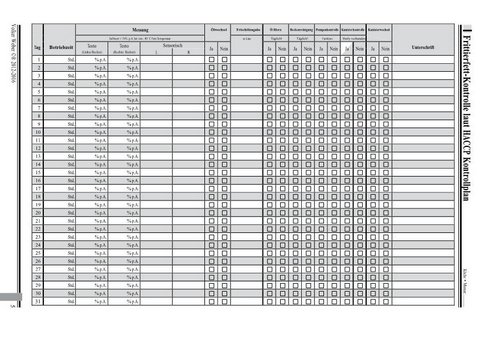

Principle 4 - Monitor CCP

.The HACCP

team will describe monitoring procedures for the

measurement of the critical limit at each

critical control point. Monitoring procedures

should describe how the measurement will be

taken, when the measurement is taken, who is

responsible for the measurement and how

frequently the measurement is taken during

production.

Principle 5 - Establish Corrective

Action .Corrective actions are the procedures

that are followed when a deviation in a critical

limit occurs. The HACCP team will identify the

steps that will be taken to prevent potentially

hazardous food from entering the food chain and

the steps that are needed to correct the

process. This usually includes identification of

the problems and the steps taken to assure that

the problem will not occur again.

Principle 6 -

Verification

.Those activities, other than

monitoring, that determine the validity of the

HACCP plan and that the system is operating

according to the plan. The HACCP team may

identify activities such as auditing of CCP's,

record review, prior shipment review, instrument

calibration and product testing as part of the

verification activities.

Principle 7 -

Recordkeeping

.A key component of the HACCP plan

is recording information that can be used to

prove that the a food was produced safely. The

records also need to include information about

the HACCP plan. Record should include

information on the HACCP Team, product

description, flow diagrams, the hazard analysis,

the CCP's identified, Critical Limits,

Monitoring System, Corrective Actions,

Recordkeeping Procedures, and Verification

Procedures. HACCP Does not Stand Alone! The

application of HACCP does not stand alone in a

food processing facility. The plan must be built

on other food safety programs. Good

Manufacturing Practices (GMP) that are practiced

by the processing facility will support HACCP

plan and will address food safety and food

quality issues that are not critical for the

reduction of food safety hazards. Sanitation

Standard Operating Procedures (SSOP's) are

required in federally inspected meat and poultry

operations and address procedures for clean

facilities, equipment and personnel that are

necessary for all products produced in a

facility.

Check out this sample files

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

| Final HACCP Book | HACCP working sheets | |||

.jpg) |

.jpg) |

.jpg) |

|

|